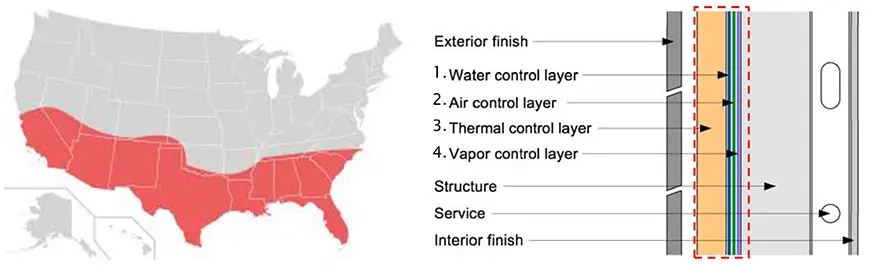

Written By: Matt Drewes | October 30, 2017In the past a building’s enclosure were far less complicated. The building’s architecture often reflected how the building works. In other words, the architecture reflected what area in the world it was located; factors like site orientation, using the natural topography and foliage to help a buildings Performance; a building’s shape and size can also influence how the exterior environments can affect the building’s performance. Often you had one feature of the buildings enclosure serving multiple purposes. However, today we can actively alter the interior environments regardless of how harsh the exterior environments are. All we have to do is adjust the little display located on the wall to whatever makes us comfortable. This modern luxury has drastically altered where and how we live. In the 1950 the percentage of the us population living within the sunbelt was around 28 percent, that number had grown to roughly 40 percent by the year 2000. (Rosen, Rebecca J. How the Air Conditioner Made Modern America, The Atlantic 2011) We also live in a global economy, a society were ideas and goods are as readily available as the air we breathe. Thanks to these innovations, modern architecture has now taken hold, a style that is no longer dependent on its immediate environment to drive the buildings design, rather modern technological innovations. However, I’m not saying that because of modern technology we can do away with the “old way of doing things”, but I am saying we can use it to make things better!

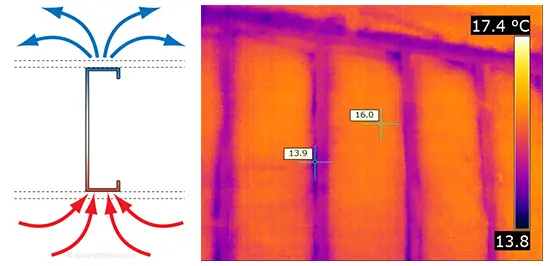

Unfortunately, the cost of actively altering the interior environment with air conditioning is expensive. Therefore, having an efficient building enclosure is pivotal to further separate the comfortable interior environment form the harsh unforgiving exterior environment. The modern building enclosure has arranged its complicated barrier system to effectively manage and repel the worst mother nature can dish out. First, there is the durable exterior finish layer, which can be anything from brick and fiber cement boards to lap siding or other types of rain screens. This layer is never completely weather tight and must allow a small space for air circulation and drainage of any excess moisture. The second layer needs to be the thermal barrier. This layer, which would typically be expected within the support structure between studs has now moved to the exterior of the control layers. This is because of thermal bridging, the studs located within the wall have a far less R-value than the surrounding insulation, this lack of insulation essentially creates a gap were heat loss can occur.Moving the insulation to the outside and using semi-rigid MFI, XPS, EPS, or PIC insulation allows for a more efficient, continuous thermal barrier and a more effective R-Value. Additionally, moving the insulation to the exterior also helps mediate the amount of moisture that penetrates to the third layer, the moisture barrier. The moisture barrier is the layer specifically designed to keep water out. This layer can be either permeable or impermeable depending on what kind of moisture mitigation system is in place.The moisture barrier is often combined with the fourth layer, the air barrier. Just as thermal bridging can occur in areas that lack insulation, air leakage can drastically reduce the efficiency of a building by allowing exterior air to enter and all that nice, comfortable, conditioned air out. The fifth and last barrier is the vapor barrier, this layer is designed to prevent the movement of water vapor molecules through microscopic openings in porous materials like wood, gypsum, and concrete. Vaper tends to move from the warm to cold and condense into water droplets, this process can start to pose a problem when the thermal insulation is located within the support wall, vapor passes through and condenses on the cold side and could starts to develop mold. Therefore, the vapor barrier is located on the interior side of the barrier layers, to remain on the warm side of the buildings enclosure.

Although modern technology has seemingly made the building enclosure more complicated, it has also made things extremely more efficient. The key is to break down to the individual layers by asking, “what is the purpose of this layer and how does it work with the rest of the system?”.